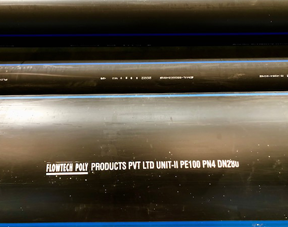

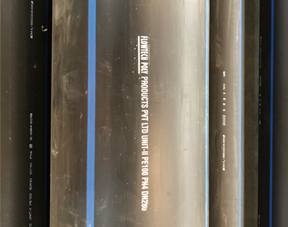

HDPE Pipes

Online/Inline Lateral Pipe

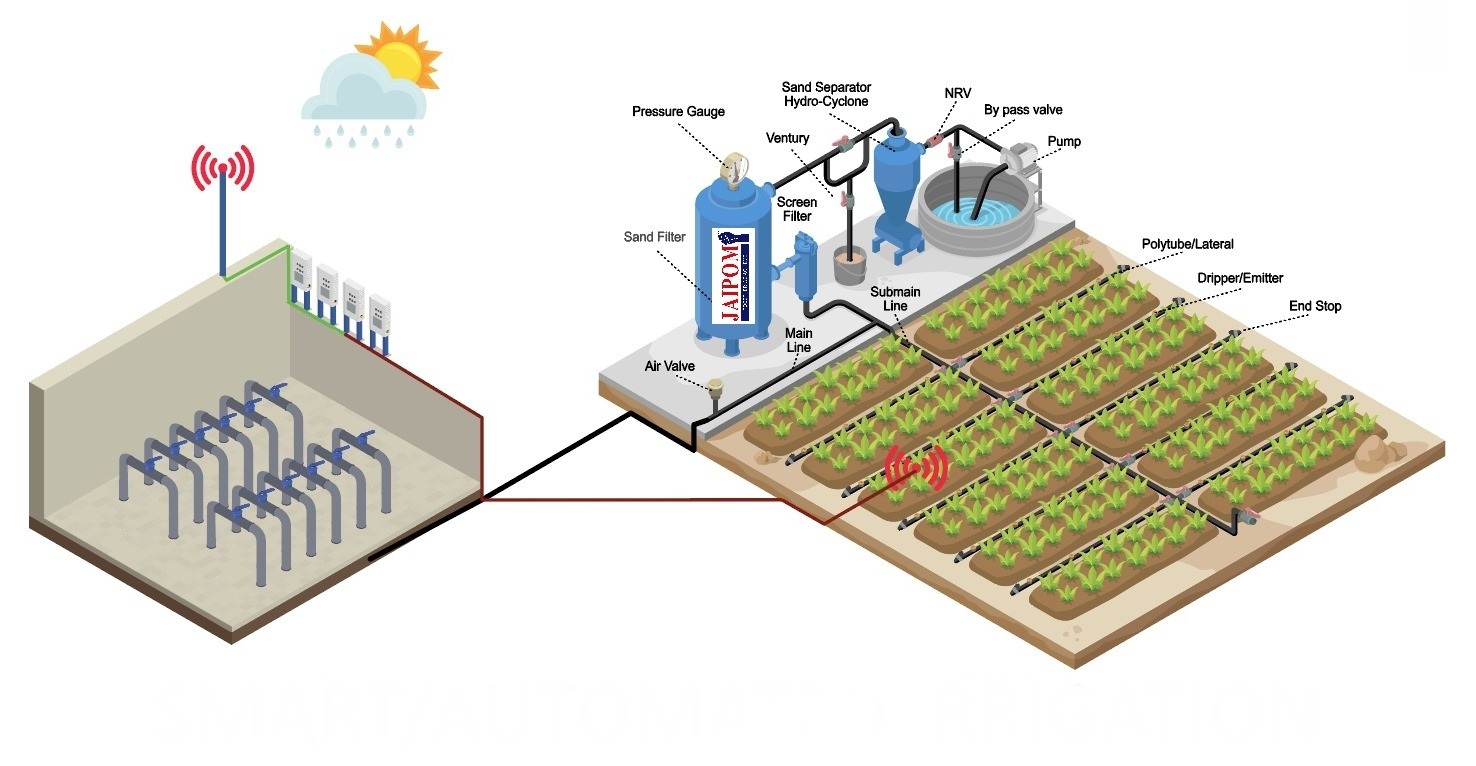

Smart Irrigation

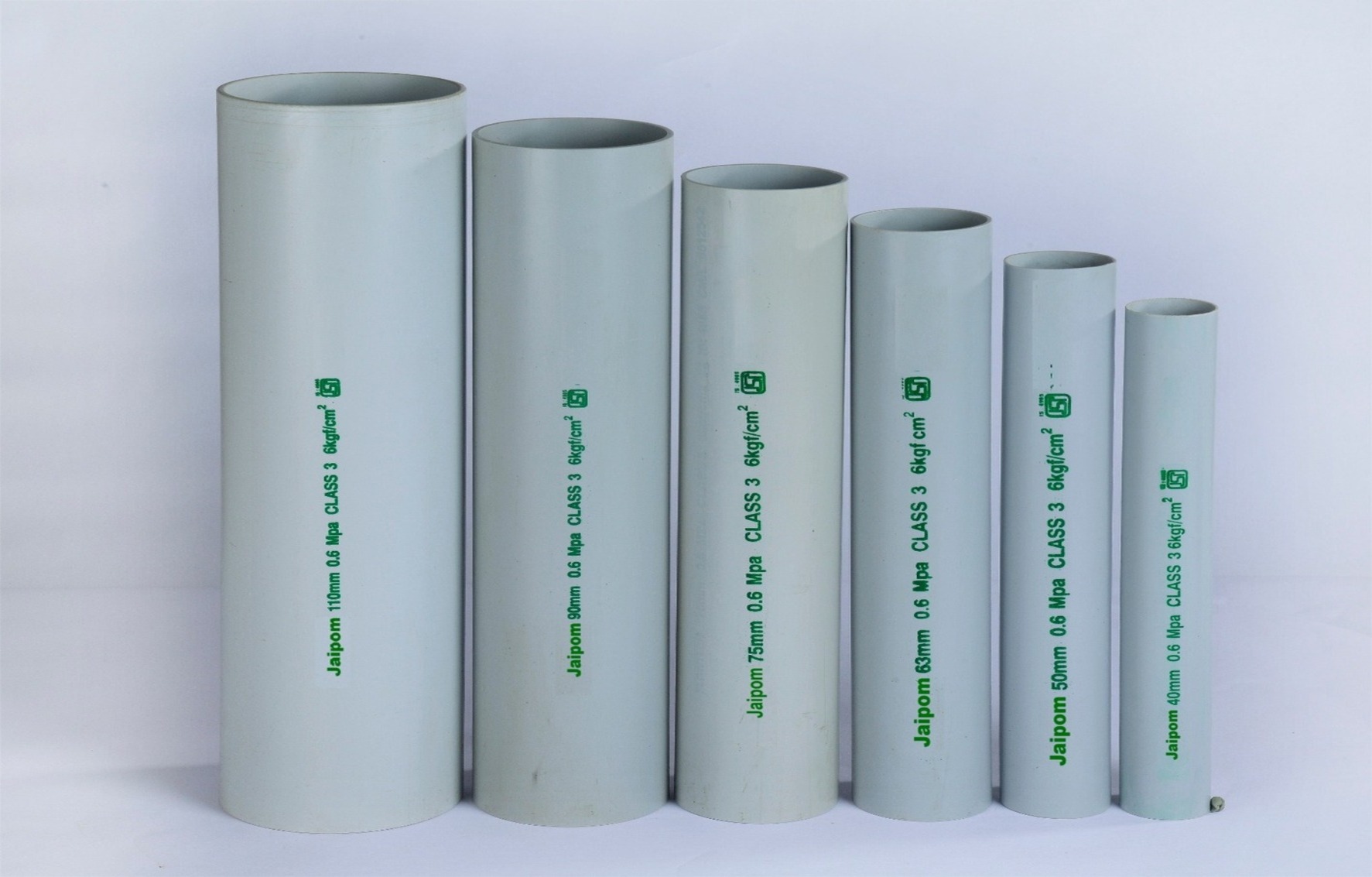

PVC Pipes

HDPE pipes - available in three material grades(PE63, PE80, PE100).

Supply of HDPE pipes when made in handy lengths and coils minimises the number of joints and also eases the process of laying out. The packaging for various sizes will be as follows.

| Upto 50mm | 500m coils / Straight lengths of 6m,9m,12m. |

|---|---|

| Between 50mm - 110mm | 300m coils / Straight lengths of 6m,9m,12m. |

| Above 110mm | Straight lengths of 6m,9m,12m. |

HDPE pipes can be used for distribution of water,waste water, slurries, chemicals ,hazardous waste and as cable ducts. It has adequate flexibility and durability to withstand environmental factors for ensuring reliable distribution.

Standard sizes are available in stock mentioned.

Special requirements met through prior order basis.

| Pipe Size (mm/inch) | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | |||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| 16mm / 1/2" | NIL | NIL | NIL | NIL | NIL | NIL | 2.1 | 2.4 | 2.6 | 3.2 | 3.3 | 3.8 |

| 20mm / 5/8" | NIL | NIL | NIL | NIL | NIL | NIL | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 |

| 25mm / 3/4" | NIL | NIL | NIL | NIL | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 | 4.2 | 4.9 |

| 32mm / 1" | NIL | NIL | 2.3 | 2.8 | 3.0 | 3.5 | 3.6 | 4.2 | 4.4 | 5.1 | 5.4 | 6.2 |

| 40mm / 1 1/4" | 2.0 | 2.4 | 2.8 | 3.3 | 3.7 | 4.3 | 4.5 | 5.2 | 5.5 | 6.3 | 6.7 | 7.6 |

| 50mm / 1 1/2" | 2.4 | 2.9 | 3.5 | 4.1 | 4.6 | 5.3 | 5.6 | 6.4 | 6.8 | 7.7 | 8.4 | 9.5 |

| 63mm / 2" | 3.0 | 3.5 | 4.4 | 5.1 | 5.8 | 6.6 | 7.0 | 7.9 | 8.6 | 9.7 | 10.5 | 11.8 |

| 75mm / 2 1/2" | 3.6 | 4.2 | 5.3 | 6.1 | 6.9 | 7.8 | 8.4 | 9.5 | 10.2 | 11.5 | 12.5 | 14.0 |

| 90mm / 3" | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.2 | 13.7 | 15.0 | 16.7 |

| 110mm / 4" | 5.3 | 6.1 | 7.7 | 8.7 | 10.0 | 11.2 | 12.3 | 13.8 | 14.9 | 16.6 | 18.4 | 20.5 |

| 125mm / 5" | 6.0 | 6.8 | 8.8 | 9.9 | 11.4 | 12.8 | 13.9 | 15.5 | 16.9 | 18.8 | 20.9 | 23.2 |

| 140mm / 5 1/2" | 6.7 | 7.6 | 9.8 | 11.0 | 12.8 | 14.3 | 15.6 | 17.4 | 19.0 | 21.1 | 23.4 | 26.0 |

| 160mm / 6" | 7.7 | 8.7 | 11.2 | 12.6 | 14.6 | 16.3 | 17.8 | 19.8 | 21.7 | 24.1 | 26.7 | 29.6 |

| 180mm / 7" | 8.6 | 9.7 | 12.6 | 14.1 | 16.4 | 18.3 | 20 | 22.2 | 24.4 | 27.1 | 30.0 | 33.2 |

All dimensions are in mm/inch Pressure rating in Kg/cm2

| Pipe Size (mm/inch) | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | ||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| 20mm / 5/8" | NIL | NIL | NIL | NIL | NIL | NIL | 2.3 | 2.7 | 2.8 | 3.3 |

| 25mm / 3/4" | NIL | NIL | NIL | NIL | 2.3 | 2.7 | 2.8 | 3.3 | 3.5 | 4.1 |

| 32mm / 1" | NIL | NIL | 2.4 | 2.8 | 3.0 | 3.5 | 3.6 | 4.2 | 4.5 | 5.2 |

| 40mm / 1 1/4" | 2.3 | 2.8 | 3.0 | 3.5 | 3.7 | 4.3 | 4.5 | 5.2 | 5.6 | 6.4 |

| 50mm / 1 1/2" | 2.9 | 3.4 | 3.8 | 4.4 | 4.6 | 5.3 | 5.6 | 6.4 | 6.9 | 7.8 |

| 63mm / 2" | 3.6 | 4.2 | 4.7 | 5.4 | 5.8 | 6.6 | 7.0 | 7.9 | 8.7 | 9.8 |

| 75mm / 2 1/2" | 4.3 | 5.0 | 5.6 | 6.4 | 6.9 | 7.8 | 8.4 | 9.5 | 10.4 | 11.7 |

| 90mm / 3" | 5.1 | 5.9 | 6.7 | 7.6 | 8.2 | 9.3 | 10.0 | 11.2 | 12.5 | 14.0 |

| 110mm / 4" | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.3 | 13.8 | 15.2 | 17.0 |

| 125mm / 5" | 7.1 | 8.1 | 9.3 | 10.5 | 11.4 | 12.8 | 13.9 | 15.5 | 17.3 | 19.3 |

| 140mm / 5 1/2" | 8.0 | 9.0 | 10.4 | 11.7 | 12.8 | 14.3 | 15.6 | 17.4 | 19.4 | 21.6 |

| 160mm / 6" | 9.1 | 10.3 | 11.9 | 13.3 | 14.6 | 16.3 | 17.8 | 19.8 | 22.1 | 24.6 |

| 180mm / 7" | 10.2 | 11.5 | 13.4 | 15.0 | 16.4 | 18.3 | 20.0 | 22.2 | 24.9 | 27.6 |

| 200mm / 8" | 11.4 | 12.8 | 14.9 | 16.6 | 18.2 | 20.3 | 22.3 | 24.8 | 27.6 | 30.6 |

| 225mm / 9" | 12.8 | 14.3 | 16.7 | 18.6 | 20.5 | 22.8 | 25.0 | 27.7 | 31.1 | 34.5 |

| 250mm / 10" | 14.2 | 15.9 | 18.6 | 20.7 | 22.8 | 25.3 | 27.8 | 30.8 | 34.5 | 38.2 |

| 280mm / 11" | 15.9 | 17.7 | 20.8 | 23.1 | 25.5 | 28.3 | 31.2 | 34.6 | 38.7 | 42.8 |

| 315mm / 12 1/2" | 17.9 | 19.9 | 23.4 | 26.0 | 28.7 | 31.8 | 35.0 | 38.7 | 43.5 | 48.1 |

| 355mm / 14" | 20.1 | 22.4 | 26.3 | 29.2 | 32.3 | 35.8 | 39.5 | 43.7 | 49.0 | 54.1 |

| 400mm / 16" | 22.7 | 26.4 | 29.7 | 34.4 | 36.4 | 42.1 | 44.5 | 51.4 | 55.2 | 63.7 |

All dimensions are in mm/inch Pressure rating in Kg/cm2

| Pipe Size (mm/inch) | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | Wall Thickness | ||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| 20mm / 5/8" | NIL | NIL | NIL | NIL | NIL | NIL | 1.9 | 2.3 | 2.3 | 2.8 |

| 25mm / 3/4" | NIL | NIL | NIL | NIL | NIL | NIL | 2.3 | 2.8 | 2.9 | 3.4 |

| 32mm / 1" | NIL | NIL | NIL | NIL | 2.4 | 2.9 | 2.9 | 3.4 | 3.7 | 4.3 |

| 40mm / 1 1/4" | NIL | NIL | 2.4 | 2.9 | 3.0 | 3.5 | 3.7 | 4.3 | 4.6 | 5.3 |

| 50mm / 1 1/2" | 2.3 | 2.8 | 3.0 | 3.5 | 3.7 | 4.3 | 4.6 | 5.3 | 5.7 | 6.3 |

| 63mm / 2" | 2.9 | 3.4 | 3.8 | 4.4 | 4.7 | 5.4 | 5.7 | 6.5 | 7.1 | 8.1 |

| 75mm / 2 1/2" | 3.5 | 4.1 | 4.5 | 5.2 | 5.6 | 6.4 | 6.8 | 7.7 | 8.5 | 9.6 |

| 90mm / 3" | 4.1 | 4.8 | 5.4 | 6.2 | 6.7 | 7.6 | 8.2 | 9.3 | 10.2 | 11.5 |

| 110mm / 4" | 5.0 | 5.7 | 6.6 | 7.5 | 8.1 | 9.2 | 10.0 | 11.2 | 12.4 | 13.9 |

| 125mm / 5" | 5.7 | 6.5 | 7.5 | 8.5 | 9.2 | 10.4 | 11.3 | 12.7 | 14.1 | 15.8 |

| 140mm / 5 1/2" | 6.4 | 7.3 | 8.4 | 9.5 | 10.3 | 11.6 | 12.7 | 14.2 | 15.8 | 17.6 |

| 160mm / 6" | 7.3 | 8.3 | 9.6 | 10.8 | 11.8 | 13.2 | 14.5 | 16.2 | 18.1 | 20.2 |

| 180mm / 7" | 8.2 | 9.3 | 10.8 | 12.1 | 13.3 | 14.9 | 16.3 | 18.2 | 20.3 | 22.6 |

| 200mm / 8" | 9.1 | 10.3 | 12.0 | 13.4 | 14.8 | 16.5 | 18.1 | 20.2 | 22.6 | 25.1 |

| 225mm / 9" | 10.3 | 11.6 | 13.5 | 15.1 | 16.6 | 18.5 | 20.4 | 22.7 | 25.4 | 28.2 |

| 250mm / 10" | 11.4 | 12.8 | 15.0 | 16.7 | 18.4 | 20.5 | 22.6 | 25.1 | 28.2 | 31.3 |

| 280mm / 11" | 12.8 | 14.3 | 16.8 | 18.7 | 20.6 | 22.9 | 25.3 | 28.1 | 31.6 | 35.0 |

| 315mm / 12 1/2" | 14.4 | 16.1 | 18.9 | 21.0 | 23.2 | 25.8 | 28.5 | 31.6 | 35.5 | 39.3 |

| 355mm / 14" | 16.2 | 18.1 | 21.2 | 23.6 | 26.2 | 29.1 | 32.1 | 35.6 | 40.0 | 44.2 |

| 400mm / 16" | 18.2 | 21.2 | 23.9 | 27.7 | 29.5 | 34.2 | 36.2 | 41.9 | 45.1 | 52.1 |

All dimensions are in mm/inch Pressure rating in Kg/cm2

Flowtech Products are known for their precision, efficiency, dependability and performance. The products are economical and require very little maintenance.

Available Sizes: 1”, 1 ¼”, 1 ½”, 2”, 2 ½”X2”, 2 ½”, 3”, 4”

Available Sizes: ½”, 5/8”, ¾”, 1”, 1 ¼”, 1 ½”, 2”, 2 ½”, 3”, 4”

Flowtech Products are known for their precision, efficiency, dependability and performance.The products are economical and require very little maintenance. The Company’s products are Drip Irrigation Systems, Sprinkler Irrigation Systems, HDPE Pipes, PVC & UPVC Pipes.

Flowtech Products are known for their precision, efficiency, dependability and performance.The products are economical and require very little maintenance. The Company’s products are Drip Irrigation Systems, Sprinkler Irrigation Systems, HDPE Pipes, PVC & UPVC Pipes.